Mold Core and Cavity Making Kehui Mold Co., Limited

Pengertian Mold Cavity Baik, jadi, apa itu sebenarnya yang disebut dengan mold cavity ini? Berikut adalah penjelasan dari kamus teknik Keinsinyuran. Ruang dalam cetakan yang diisi dengan logam cair untuk membentuk casting pada pemadatan.

Multi Cavity Mold Archives WELSON MOLD

At Plastopia, we will analyze the wall thickness in our DFM report. It will show you the potential sink marks, and you will need to modify the parts to eliminate or reduce them. TIP: For small size of plastic parts, the sink marks could be eliminated by adjusting injection condictions.

Mold Cavity for Injection Molding Plastopia

Expandable Cavities (EX-CAV™) mold undercuts such as threads, dimples, and protrusions outside of molded parts. The patented EX-CAV™ design eliminates the engineering, maintenance, and machining required for side action mechanisms which results in smaller molds or higher mold cavitation.. B-Side Expandable Cavities are anchored into the ejector plates and actuated during the machine knock.

Multi Cavity Injection Molds vs. Family Injection Molds The Rodon Group®

In multi-cavity injection mold, Molten plastic flow balancing is a challenging task. Three-Plate Mold. Three plate injection mold consists of two parting planes and mold splits into three sections. Therefore runners and components can be located on different parting planes. In three plate molds, the runner is ejected separately to the molded part.

A Primer on Mold Cavities The Toolroom

Discover the power of 3D mold design in the cloud with an intuitive, purpose-built set of tools that streamlines the creation of mold core, cavity and inserts. Quickly design molds directly in your browser and reduce time to market by utilizing the power of the 3D EXPERIENCE® platform, which connects teams and their respective data in one.

SingleCavity vs. MultiCavity Injection Molding Fast Radius

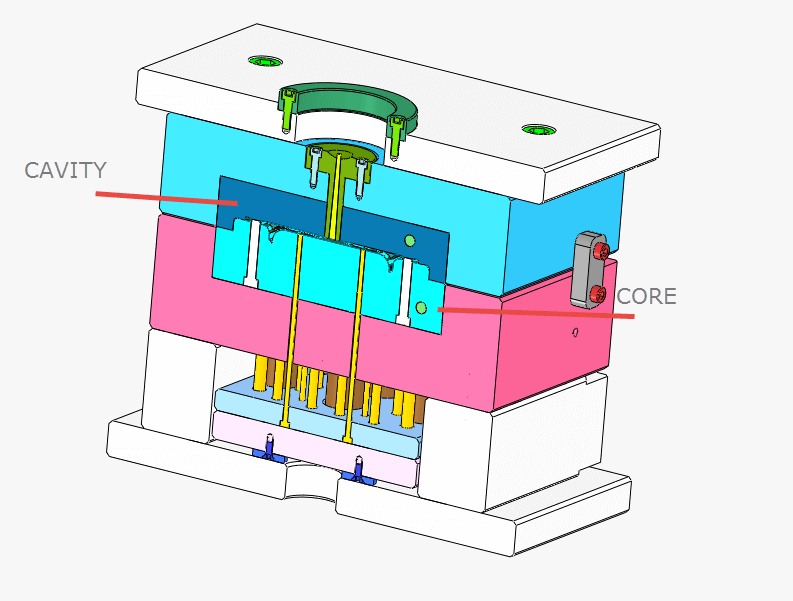

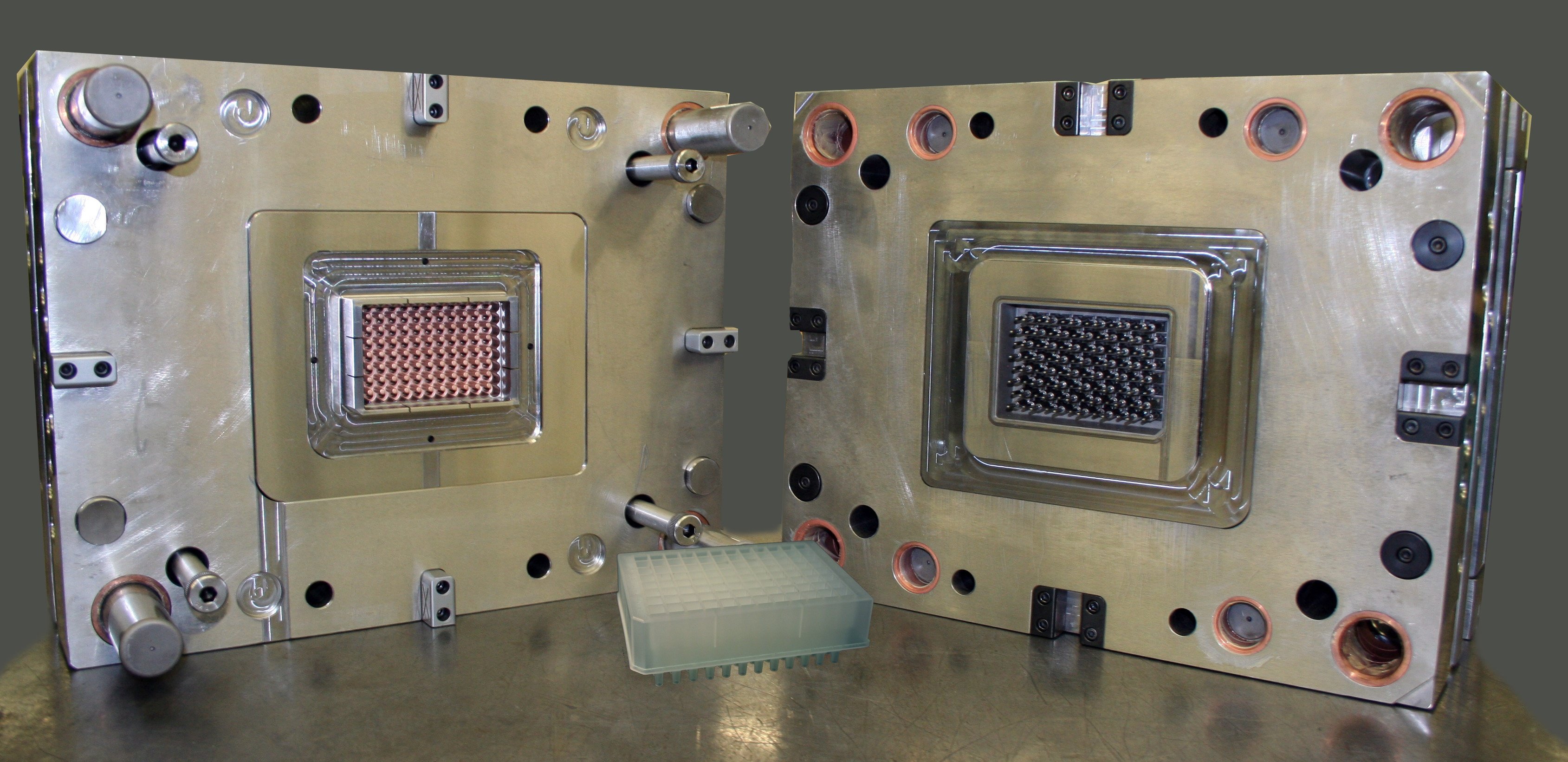

A mold cavity, also called a die cavity or simply cavity, is a hollow space or void within a mold that defines the final molded product's shape, size, and surface details. It is the part of the mold where the molten material is injected and solidified to form the desired object.

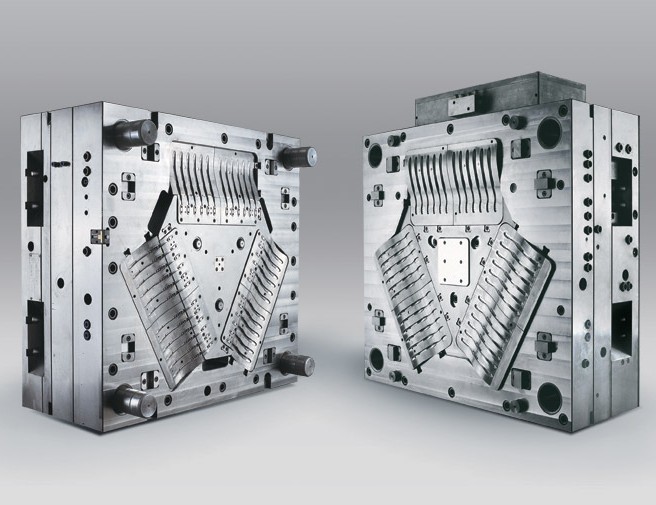

Single / Multi Cavity Mold

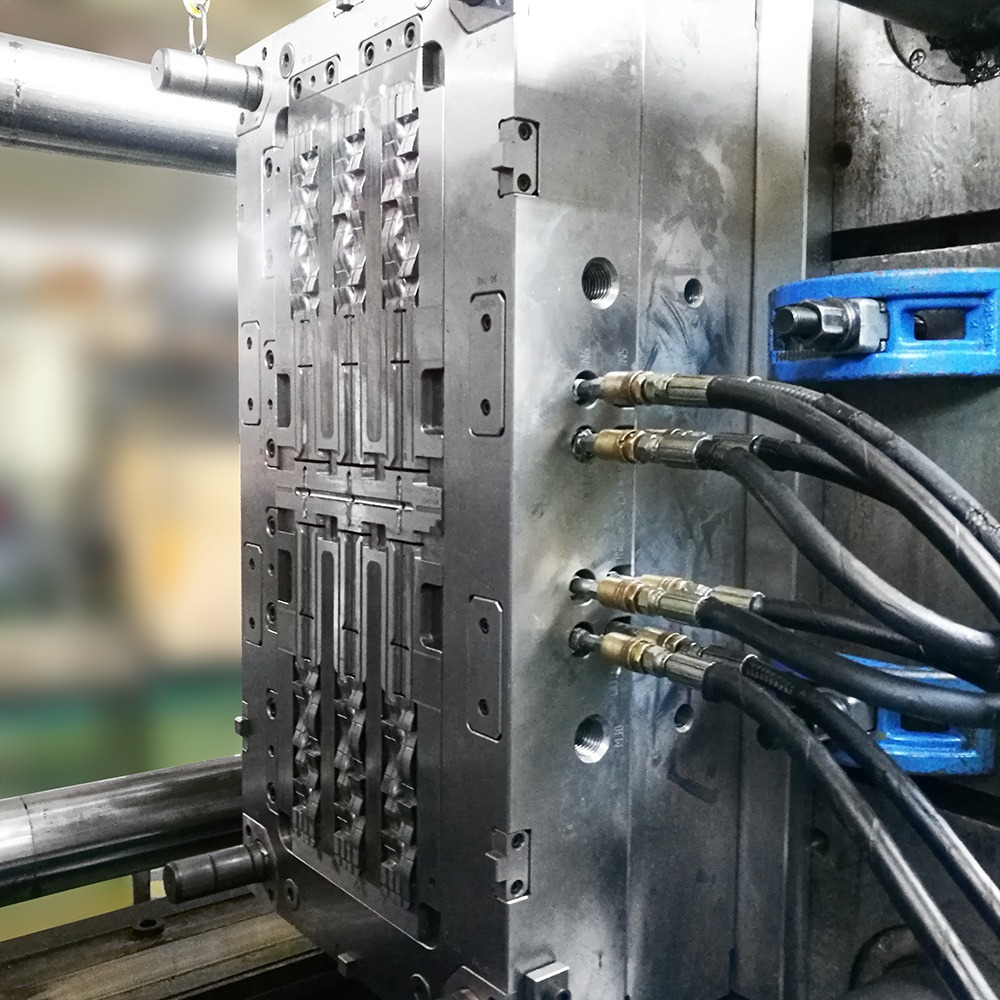

1. Mold Venting Design Points The mold vent should be designed on the cavity side of the parting surface, in order to facilitate mold manufacturing and cleaning. Try to set it at the end of the material flow and the thicker section of the plastic part.

Tool shop update 16 cavity plastic injection mold CJ Industries

Jumat, 08 April 2016 2.2 Mold Base dan Cavity Mold base adalah kumpulan plate, pin, bush dan baut yang dirangkai menjadi satu, disitu akan dibuat atau diletakkan core dan cavity. Berbagai komponen pendukung juga akan di assy pada mold base. #Standard dimensi moldbase yang dipakai adalah Futaba.

MOLD DESIGN Create Two Cavity Mold with Insert Core YouTube

Cavity dan core adalah bagian penting dari sebuah mold supaya bisa menghasilkan produk yang berkualitas sesuai dengan yang diinginkan. Pada video ini diberik.

Mold Cavity for Injection Molding Plastopia

1. Pelat Klem Tetap atau Pelat Atas 2. Pelat Stripper 3. Plat Mold Tetap atau Plat Cavity. 4. Pelat Cavity Bergerak atau Pelat Cavity 5. Back up Plate atau Plat Penopang 6. Block Spacer 7. Pelat Penahan Ejector 8. Ejector Plate 9. Pelat Penjepit Bergerak atau Pelat Bawah Plat Mold

Multi Cavity Mold

Cavity - Ketika pelat tetap dan pelat bergerak bersentuhan, cavity adalah rongga yang dibentuk oleh proses pemesinan atau pemotongan. Dan akan menentukan bentuk produk Sprue - sprue adalah lubang yang berada di tengah Fix Plate. Plastik cair mengalir dari sprue untuk mengisi cavity.

Injection Mold Focus, Part 1 SingleCavity Molds

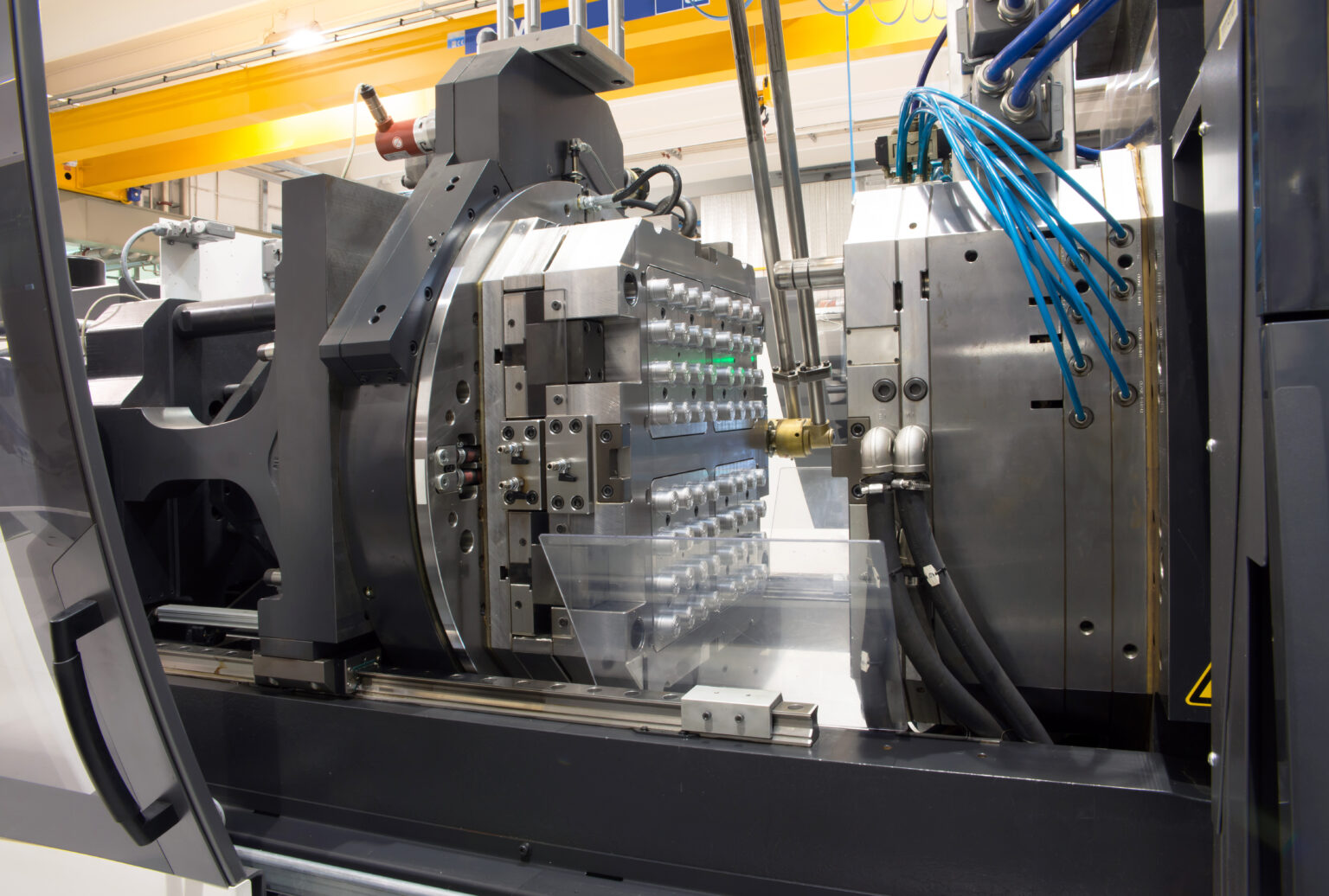

The mold's cavity side stays put, while the core side rotates. A runner, located on the mold's separating surface, is a fixed component of the tool. The injection-molded product and the runner remain in the movable mold section after the molding process is complete. Afterward, the runner and injection component is taken off the cutting edge.

Multi Cavity Mold less your parts will cost economical in mass production

Sisi Cavity adalah sisi yang dibangun untuk mengalirkan bahan plastik dari nozzle ke bagian cavity. Pada dasarnya mereka terdiri dari sprue dan runner. Konstruksi sisi core untuk membuat bentuk pada core, sistem demolding dan sistem injeksi. Pada sisi ini kami merancang sistem ejeksi.

Membuat Cavity dan Core untuk Mold menggunakan Solidworks YouTube

Plasticating atau Injection Unit Gambar 3. Injection Molding: Pengertian, Bagian dan Prosesnya Sumber: plasticmoulds.net Injection unit memiliki tiga fungsi utama, yang pertama yaitu untuk memanaskan dan melelehkan bahan baku yang akan masuk melalui bagian hopper. Setelah meleleh, bahan baku tersebut kemudian diinjeksikan ke dalam cavity.

Mold Cavity for Injection Molding Plastopia

Definition of Mold Cavity. The cavity refers to the impression or void space within a mold where the molten plastic is injected and forms the desired shape of the part. The cavity has the identical geometry as the part, just in reverse. 3. Types of Mold Cavities.

A Primer on Mold Cavities The Toolroom

In multiple cavity moulds, each cavity can be identical and form the same parts or can be unique and form multiple different geometries during a single cycle. Moulds are generally made from tool steels, but stainless steels and aluminium moulds are suitable for certain applications.